Description

DDM-3030 Diameter Measurer Monitor and Controller (Temporarily suspended, replaced by DDM2050 )

In the cable production process, the thickness of the insulation layer is jointly controlled by the speed of the tractor and the extruder.

Cable diameter controller DDM3030 used in the cable production line, the controller measures the diameter of the cable in real-time, and outputs an analog signal to control the speed of the tractor and extruder, so, the thickness of the insulation layer will be controlled in a setting range.

DSP-3S/3D Diameter Remote Display is for DDM-3030, it offers a remote display, the measuring result will be shown on the display.

The Cable diameter controller also called Optical Micrometer, detecting diameter with laser and CCD technology, detecting diameter with laser/ infrared ray and CCD technology, it was designed for wires, cables and tubes, which not only measure and display diameter and deviation online, but also automatically control diameter of wire according to user’s setting

Includes features listed but not limited as below.

- Suitable for online measurement of any round wires, cable, fiber, tube, etc.

- Non-contact measurement, high-speed inspection, high precision, and stable performance.

- Inside PID regulation module.

- Revolving operating panel.

- RS485 communication interfaces, Modbus protocol.

- Wide range of applications.

A complete set of the controller includes a DDM-3030 diameter measuring head, measuring head support and a separate DSP-3A Monitor.

Diameter Monitor display

DSP-3S/3D Diameter Remote Display is for DDM-3030, it offers a remote display, the measuring result will be shown on the display.

Diameter Monitor display

Technical Parameters (Specifications)

| Model No. | DDM-3020 | DDM-3030 |

| Product Diameter | 0.2 ~18 mm | 0.2 ~28 mm |

| Accuracy | ± 2 µm | ± 2 µm |

| Exposure Time | 200 μS | 200 μS |

| Measuring Rate | 1800 measurements/sec/axis | 1800 measurements/sec/axis |

| Interfaces | RS-485 | RS-485 |

| Power Supply | 100 – 240 V AC ± 10 %, 50/60 Hz, 20 VA | 100 – 240 V AC ± 10 %, 50/60 Hz, 20 VA |

| Dimensions | 100 x 100 x 432 mm | 100 x 100 x 432 mm |

| Packing size: | 615 x 330 x 280 mm | 615 x 330 x 280 mm |

| Weight | 11 KG | 11 KG |

Operating condition

| Operating Temperature | 0 ~ 45 C |

| power consumption | 20 VA |

| Relative humidity | Less than 90% without condensed water |

Application and Features

DDM-3030 Diameter Measurer Monitor and Controller is used for online diameter measurement and control for electric wire and cable, optic fiber cable, tubes, and wires. compared with the previous generation products, the 3rd generation controller is characterized by All digital image process technique and dedicated ultra-large-scale integrated circuit, which ensures high stability, compact size, and low power consumption.

Hardware acceleration, which provides high measuring speed up to 1800 measurements/S and makes it possible to use the Gauge as a lump & neck detector.

RS-485 communication interface which makes the controller to be connected easily to an industrial computer, PLC and touch panel.

An advanced feedback control system, which improves the control effect.

Mouthing position

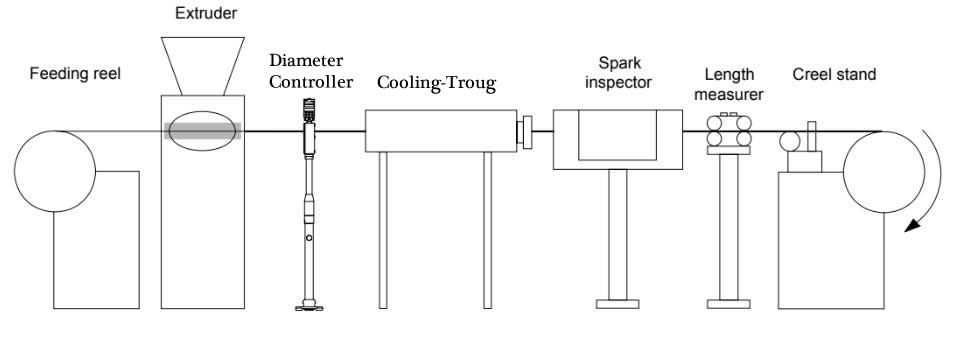

DDM-3030 Diameter Measurer Monitor and Controller can be mounted front or behind of cooling trough.

When it is mounted in the front of the cooling trough, an optimized controlling effect may be obtained through in-time feedback due to the proximity of the measuring head to the extruder. But at this time the plastic coating is not cured, so the set nominal value must be accordingly.

Front-Of-The-Cooling-Troug-Installation

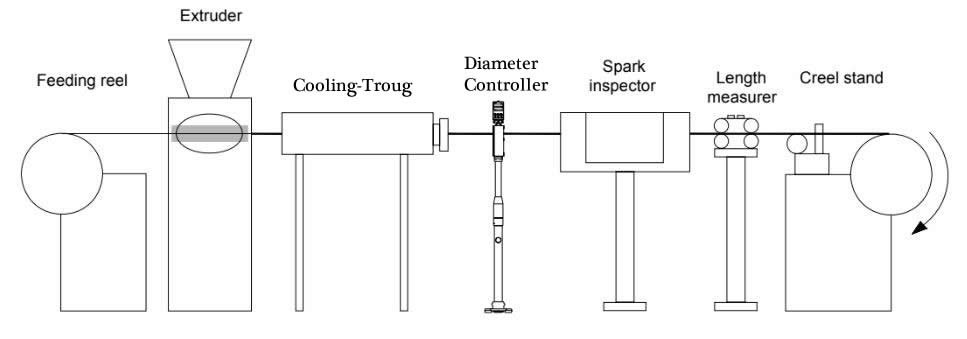

When it is mounted in the behind of the cooling trough, the measured value is the real diameter of the wire or cable. But the controlling effect is not so good because of the large control lag. Be sure to blow dry the tested wire or cable, otherwise, the measuring precision will be affected by the water coating around the wire or cable.

Behind-Of-The-Cooling-Trough-Installation

In practical using, the nominal value shall be increased appropriately according to the water content of the test object.

Check out the link below for the Application solution.

Laser Gauge Diameter Measurer Application in cable production line

Specifications of DSP-3S/3D

| Model No. | DSP-3S | DSP-3D |

| Power Supply | 100 – 240 V AC ± 10 %, 50/60 Hz, 20 VA | 100 – 240 V AC ± 10 %, 50/60 Hz, 20 VA |

| power consumption | Max 50 VA | Max 50 VA |

| Display Mode | 7 Segments LED digital | 7 Segments LED digital |

| Display range | 0~99.999 mm | 0~99.999 mm |

| Interfaces | RS-485 | RS-485 |

| Transfer Distance | Max 1000m | Max 1000m |

| Dimensions | 585 x 205 x 125 mm | 585 x 205 x 125 mm |

| Weight | 5 KG | 5 KG |

DSP-3A Monitor Specifications

| Power supply: | 100 ~ 240VAC, 50~60Hz |

| Power consumption: | < 5W |

| Operating temperature: | 0~45 ℃ |

| Atmospheric humidity: | ≤ 90% (free of condensed water) |

| Display format: | 5-digit LED digital display |

| Comm interface | RS-485 |

| Max commun distance: | 1000 m |

| Control input: | – 10V ~ +0V, input impedance 50 kΩ |

| Control output: | – 10V ~ +10V, max 10 mA |

| Alarm output: | Relay contact, max load 3A, 250VAC |

| Dimensions: | 48mm × 96mm × 112mm |

Ready for shipment

Diameter Monitor package